Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Showing all 8 results

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

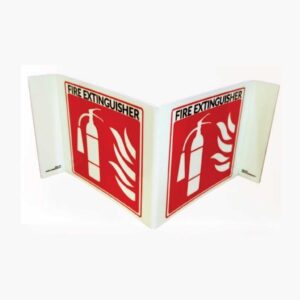

3D Fire Extinguisher Sign Plastic V Type

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Acrylic Fire Extinguisher Signs – Durable & Clear Safety Indicators

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Fire Extinguisher Flat Sign

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Fire Order Board – Essential Fire Safety Instruction Signage for Workplace Compliance

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

In Case of Fire Sign – Fire Safety Emergency Instruction Signage for Workplace Compliance

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Manual Call Point Sign – Emergency Fire Alarm Activation for Workplace Safety

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

Safe Assembly Point Sign – Essential Emergency Evacuation & Safety Guidance Signage

-

Fire Safety Signs – Emergency Egress, Extinguisher & Hydrant Guidance

V Type Fire Extinguisher Sign – High-Visibility Fire Safety Indicator for Emergency Preparedness

Introduction

Fire incidents escalate in seconds. In the first moments, people need clear, standardized cues that point to exits, extinguishers, alarms, hydrants, hose reels, fire doors, and assembly points. Well-placed fire safety signs reduce confusion, cut evacuation time, and support compliance during audits and inspections.

Globelite supplies durable fire safety sign boards aligned with recognized conventions (ISO symbol language and common OSHA/ANSI color/signal formats) and built on ACP, PVC, acrylic, reflective aluminum, or photoluminescent substrates for reliable visibility in normal and low-light conditions.

Why Fire Safety Signs Matter

- Life safety: Guide rapid wayfinding in smoke, noise, and crowd movement.

- Clarity across languages: Standard icons are instantly understood.

- Faster response: Markers help locate alarms, extinguishers, and hose reels quickly.

- Audit readiness: A visible, consistent system supports code and insurer expectations.

- Confidence & culture: Reassures staff and visitors that the site is prepared.

Standards & Color Coding (Plain-English Overview)

- Fire equipment signage: Red background + white symbol/text (extinguisher, alarm, hydrant, hose reel, fire phone).

- Safe-condition/egress signage: Green background + white symbol/text (EXIT, running man, arrows, first aid, assembly point).

- Signal words (where used): “EXIT”, “FIRE”, or common ANSI/OSHA headers (e.g., NOTICE) should be paired with clear icons.

- Local practice: Many Indian facilities pair ISO pictograms with bilingual text (English + local language) for clarity. Always follow your local code/authority having jurisdiction.

Types of Fire Safety Signs (What to Use, Where)

1) Fire Extinguisher Location & Type

Identify the exact position and type/class (e.g., Water/Foam/CO₂/Powder/Wet Chemical and A/B/C/D/K coverage). Place above or directly behind the unit for quick spotting down a corridor.

2) Fire Alarm / Manual Call Point

“Break Glass” or call point location markers at ~1.2–1.5 m height. Use arrows if not immediately visible from the approach.

3) Fire Hose Reel & Hydrant

Cabinet/valve location boards that help trained responders reach water supplies: Hose Reel, Hydrant, Sprinkler Control Valve.

4) Fire Door / Fire Compartment

Fire Door – Keep Shut / Do Not Obstruct reminders maintain compartment integrity and smoke control.

5) Emergency Exit Directional

Running-man symbol with directional arrows at turn points, intersections, and long aisles. Use photoluminescent at stairs, basements, and areas prone to power loss.

6) Assembly / Muster Point

Large, outdoor-readable boards (often reflective or ACP) marking the post-evacuation gathering zone.

7) Fire Action / Emergency Instructions

“Raise the alarm → Call numbers → Evacuate via nearest exit → Assemble → Don’t use lifts” presented as a simple step list. Add site numbers or QR to the emergency plan.

Materials & Finishes (Choose for Your Environment)

- Rigid PVC / Acrylic – Clean print, economical; indoor corridors and office areas.

- ACP (Aluminum Composite Panel) – Rigid, weather-resistant; indoor/outdoor longevity.

- Reflective Aluminum – Night and low-light visibility; parking/approach roads.

- Photoluminescent (Glow) – Self-visible during power loss; stairwells, basements, tunnels.

- Optional shields – Polycarbonate covers in impact/chemical zones.

- Finishes – UV laminate (fade resistance), anti-graffiti coat, rounded corners, pre-drilled holes, stainless fasteners.

Placement Guidelines (Make Every Sign Count)

- Extinguishers: Mark each unit; ensure visibility along the approach (not hidden behind doors or columns).

- Alarms/Call Points: Eye-level placement near exits, lobbies, and at key decision nodes.

- Hydrants/Hose Reels: Label cabinets/valves; keep the cabinet face clear of posters and notices.

- Exits & Arrows: Create a continuous breadcrumb of arrows from occupied spaces to final exits.

- Stairs & Landings: Add floor-level identifiers, “Do Not Use Lift During Fire” near elevators, and photoluminescent stair edge markers.

- Assembly Points: Use large, high-contrast boards outdoors; ensure sightlines aren’t blocked by vehicles or landscaping.

- No obstruction: Do not mount behind swing doors, stacked pallets, or noticeboards; keep clear zones around critical signs.

Buying Guide (Quick Steps)

- Map assets & routes: List extinguishers/alarms/hydrants/exits and draw evacuation paths.

- Pick substrates: PVC/Acrylic for indoor; ACP/Reflective for outdoor; Glow for egress/stairs.

- Select sizes: A3/A2 indoors; A1/custom for large halls and outdoor views.

- Language & icons: ISO pictograms + bilingual text for mixed workforces.

- Add utility: QR codes to emergency numbers, site plan, or SOP (kept short and scannable).

- Standardize templates: Keep consistent icon style, borders, and fonts across facilities.

Standard vs Photoluminescent vs Reflective (At a Glance)

| Attribute | Standard Boards | Photoluminescent (Glow) | Reflective Aluminum |

|---|---|---|---|

| Power failure | Needs lighting | Self-visible after charge | Needs external light (e.g., vehicle) |

| Best use | Indoor, lit corridors | Stairwells, basements, long egress | Outdoor, parking, perimeter routes |

| Typical size | A3/A2 | A3/A2 plus stair strips | A1/custom |

| Relative cost | Low | Medium | Medium–High |

Fire Signage by Environment (Practical Examples)

Factories & Warehouses

- Extinguisher markers at each unit; No Smoking in flammable storage; repeated EXIT arrows across long bays; Assembly Point at yard.

- Consider polycarbonate shields for boards near forklift routes.

Hospitals & Schools

- Clear Do Not Use Lift signs by elevators; photoluminescent Exit markers; simple Fire Action boards with contact numbers.

Offices & IT Parks

- Exit/arrow chains on each floor; server room extinguisher signs; assembly point in parking/outdoor common area.

Malls, Airports & Public Buildings

- Large illuminated or glow exit signage; bilingual messaging; visible hydrant/hose reel cabinets with unblocked access.

Maintenance & Audits (Keep the System Reliable)

- Monthly visual check: Clean surfaces; confirm no obstructions.

- Quarterly audit: Verify arrows form a continuous path; replace faded or damaged boards.

- After layout/process changes: Re-map routes and update signs immediately.

- Drill integration: Validate legibility and placements during fire drills; log corrective actions.

FAQs – Fire Safety Signs

1) Are fire safety signs legally required?

Sites typically must show fire equipment locations and safe egress. Follow local code and your safety officer’s guidance.

2) Do exit signs have to glow?

Use illuminated or photoluminescent exit markers for visibility during outages, especially in stairs/basements.

3) Where should extinguisher signs be placed?

Above or behind each unit so it’s visible from the approach down a corridor.

4) What materials work best outdoors?

ACP and reflective aluminum withstand weather and offer long-range visibility.

5) Can signs be bilingual?

Yes—pair pictograms with English + local language for clarity.

6) What is a Fire Action board?

A simple step list (raise alarm, call numbers, evacuate, assemble) with relevant contacts/QR.

7) How often should signs be replaced?

Replace when faded, damaged, or after layout changes. Many sites review annually during audits.

8) Do we need “Do Not Use Lift During Fire” signs?

Yes—place near every lift/elevator and on the landing opposite.

9) How big should outdoor assembly point signs be?

Go large (A1/custom) with high contrast; consider reflective for dusk/night.

10) Can we add QR codes?

Yes—link to emergency procedures, floor map, or key contacts. Keep landing pages lightweight for quick loading.

Checklist – Before You Order

- Asset map complete (extinguishers, alarms, hydrants, exits, assembly)

- Substrate chosen per location (indoor/outdoor/glow)

- Bilingual text confirmed where needed

- Sizes set for sightlines (A3/A2/A1/custom)

- Mounting method planned (anchors, tape, shield)

- Templates standardized (icons, fonts, borders)

- Maintenance cadence added to safety calendar

Conclusion

A coherent fire safety sign system turns panic into purposeful motion. With the right icons, colors, materials, and placements, people quickly locate equipment, follow exit routes, and assemble safely. Globelite’s photoluminescent, reflective, ACP, PVC, and acrylic options help you deploy a reliable, audit-ready solution across floors, buildings, and campuses.