Why Eye Protection Is Essential in Workplaces

1. Prevents Eye Injuries

Shields against chemicals, flying debris, dust, and sharp particles.

2. Protects Against Radiation

Tinted and welding goggles block UV and infrared rays.

3. Ensures Safety Compliance

Helps maintain workplace safety standards and audit requirements.

4. Improves Worker Productivity

Workers can perform tasks confidently with hazard-free vision.

5. Cost-Effective Safety

Significantly reduces medical expenses and operational downtime caused by eye accidents.

Types of Eye Protection Products

1. Safety Glasses

- Lightweight and comfortable

• Clear or tinted lenses for indoor & outdoor work

• Scratch-resistant & anti-fog coatings

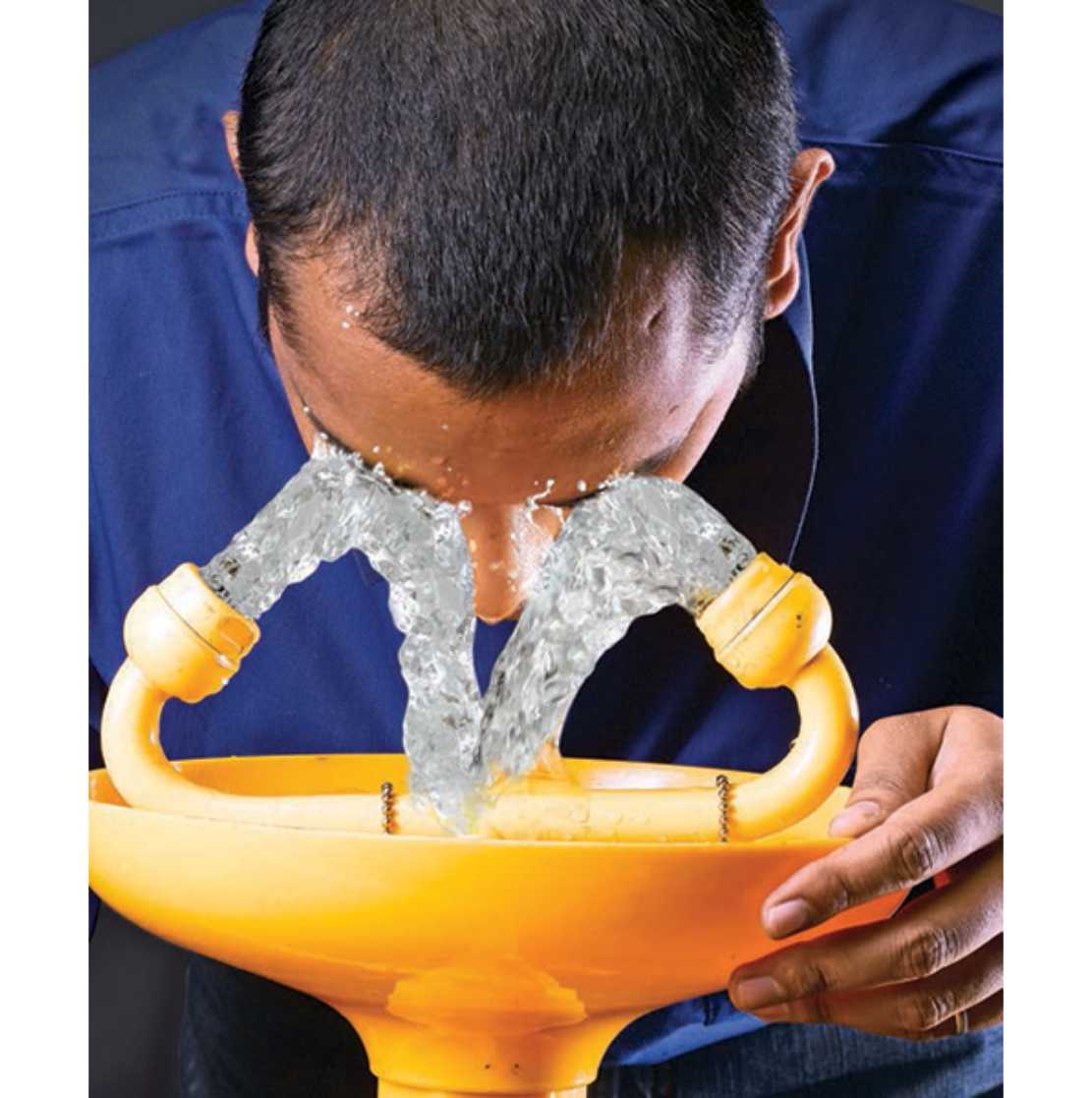

2. Safety Goggles

- Full eye coverage with tight sealing

• Chemical splash protection

• Ventilated and non-ventilated options

3. Face Shields

- Full-face coverage

• Ideal for welding, grinding, cutting, and high-spark environments

• Can be worn with safety glasses for double-layer protection

4. Specialized Eye Protection

- Auto-darkening welding helmets

• Laser safety glasses

• Specialized UV/IR lenses

Applications of Eye Protection

- Manufacturing Plants & Factories – Protection from sparks, dust & machinery hazards

• Construction Sites – Shields against high-speed debris

• Chemical Plants & Laboratories – Essential for chemical splash prevention

• Welding & Metalworking Units – Protection from sparks, burns & radiation

• Healthcare & Research Facilities – Shields against fluids, particles & biohazards

Benefits of Using Eye Protection

✔ Enhanced Safety – Prevents workplace-related eye injuries

✔ Wide Range of Options – Glasses, goggles, shields & specialized gear

✔ Durability – Polycarbonate shatter-resistant lenses

✔ Comfortable Fit – Adjustable frames, lightweight materials

✔ Clear Vision – Anti-fog and scratch-resistant properties

Buying Guide – Choosing the Right Eye Protection

- Type of Hazard:

Choose safety goggles, welding shields, or chemical splash protection based on workplace risks. - Lens Type:

Clear, tinted, or shaded lenses depending on indoor/outdoor use. - Durability:

Opt for polycarbonate, impact-resistant lenses. - Comfort:

Lightweight design with adjustable straps or frames. - Certification:

Ensure compliance with OSHA, ANSI, CE, ISO standards.

Safety Glasses vs Goggles vs Face Shields

| Feature | Safety Glasses | Safety Goggles | Face Shields |

| Coverage | Basic | Full eye seal | Full-face |

| Comfort | High | Medium | Medium |

| Protection Level | Low–Medium | High | Very High |

| Best Use Case | General work | Chemicals, dust | Welding, grinding |

Maintenance & Storage Tips

- Clean lenses regularly using mild soap and water

• Store gear in protective cases to avoid scratching

• Inspect straps, frames, and lenses frequently

• Replace damaged or worn-out equipment immediately

FAQs – Eye Protection

1. Why is eye protection important?

To prevent injuries caused by dust, chemicals, sparks, and other workplace hazards.

2. Which is better: safety glasses or safety goggles?

Glasses are suitable for general work; goggles offer a tight seal for high-risk environments.

3. Can face shields replace safety glasses?

No — shields must be worn with safety glasses for maximum protection.

4. Are the products certified?

Yes, they meet OSHA, ANSI, CE, ISO safety compliance standards.

5. Do safety glasses protect against UV?

Yes, specialized lenses provide UV and IR protection.

6. Can the same goggles be used for chemicals and welding?

No — use application-specific protective gear.

7. Are anti-fog lenses available?

Yes, many goggles and glasses come with built-in anti-fog functionality.